Yesterday was a snow day and I spent some time learning more about Solidworks and the Shapeoko.

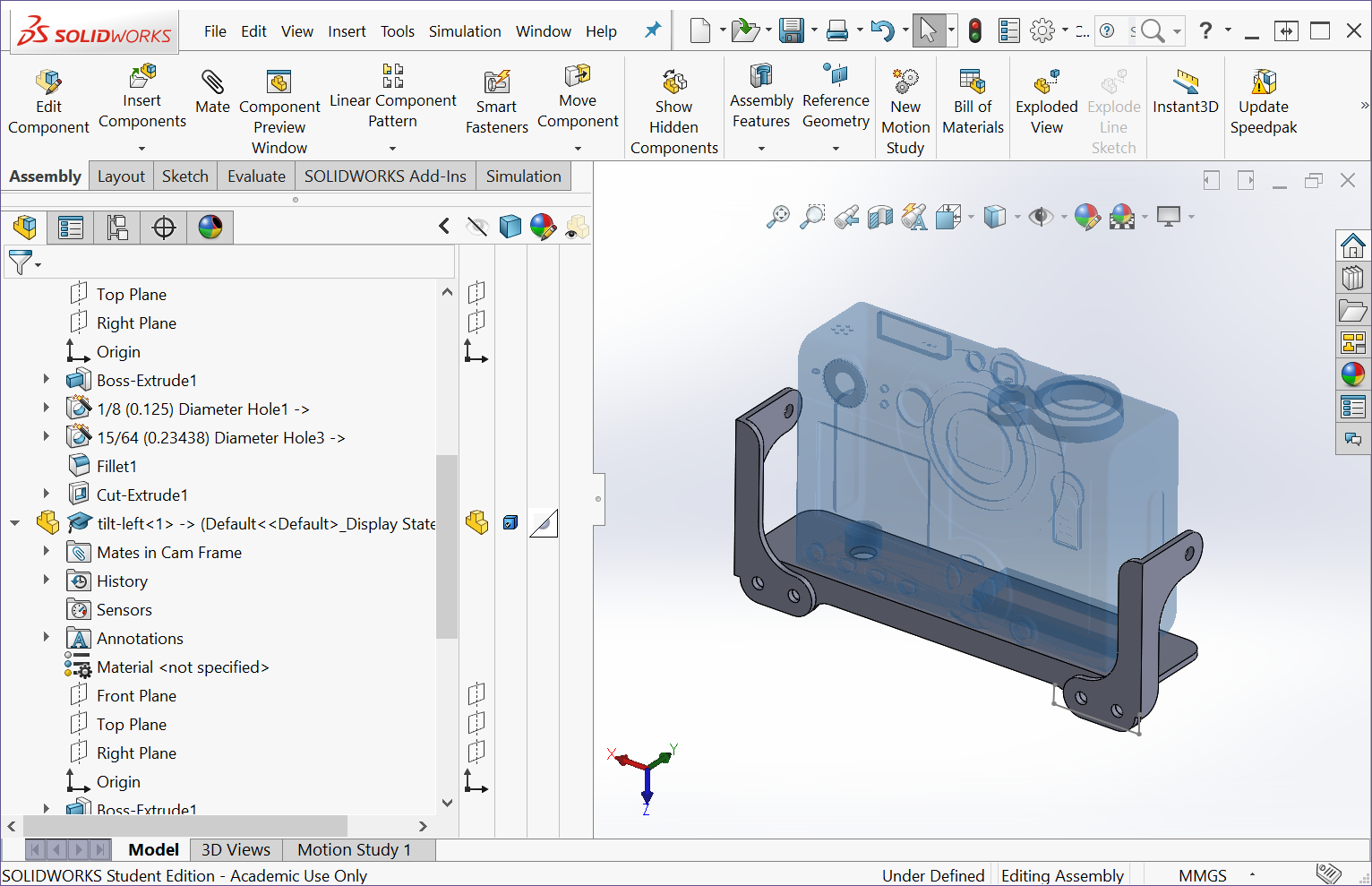

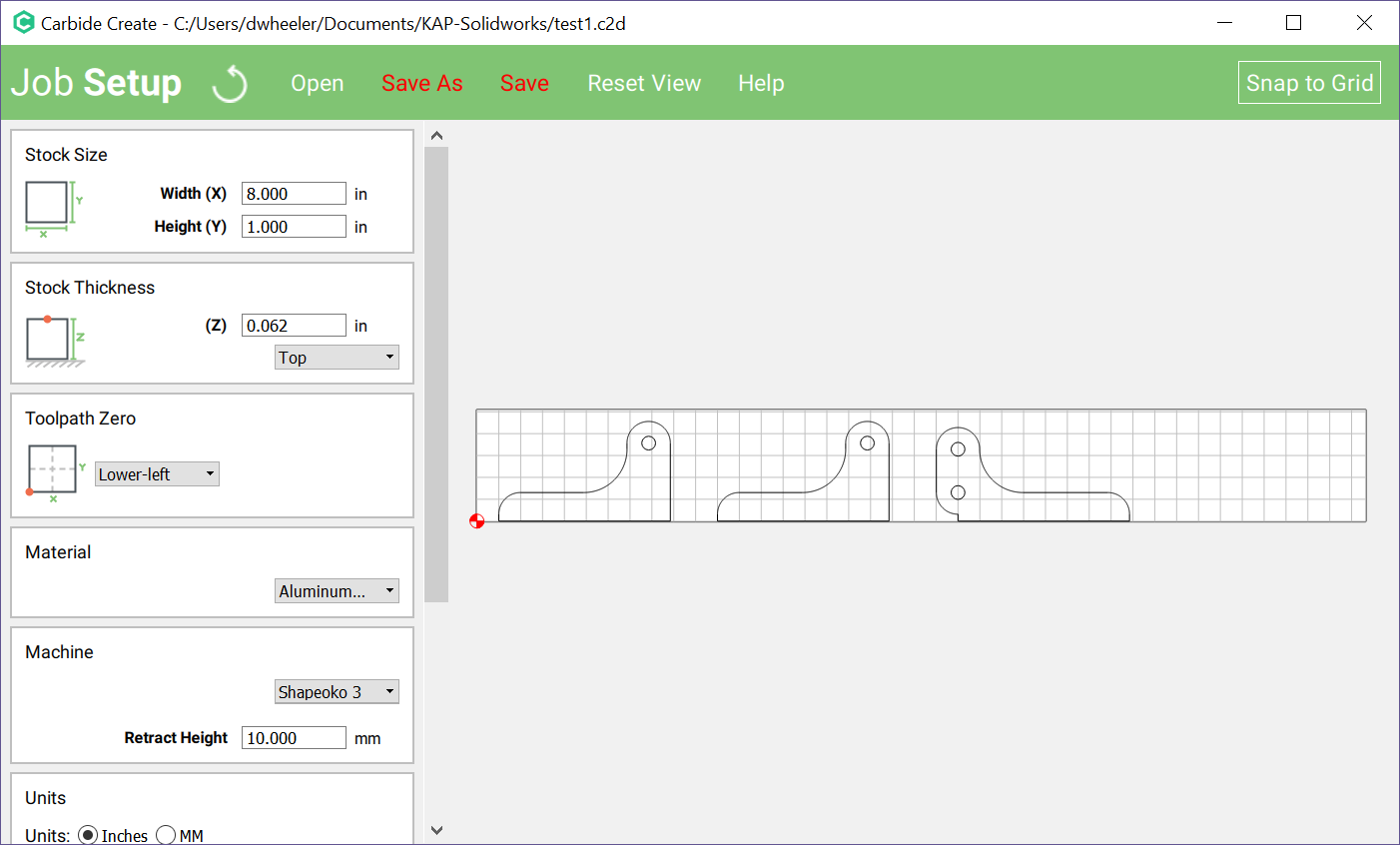

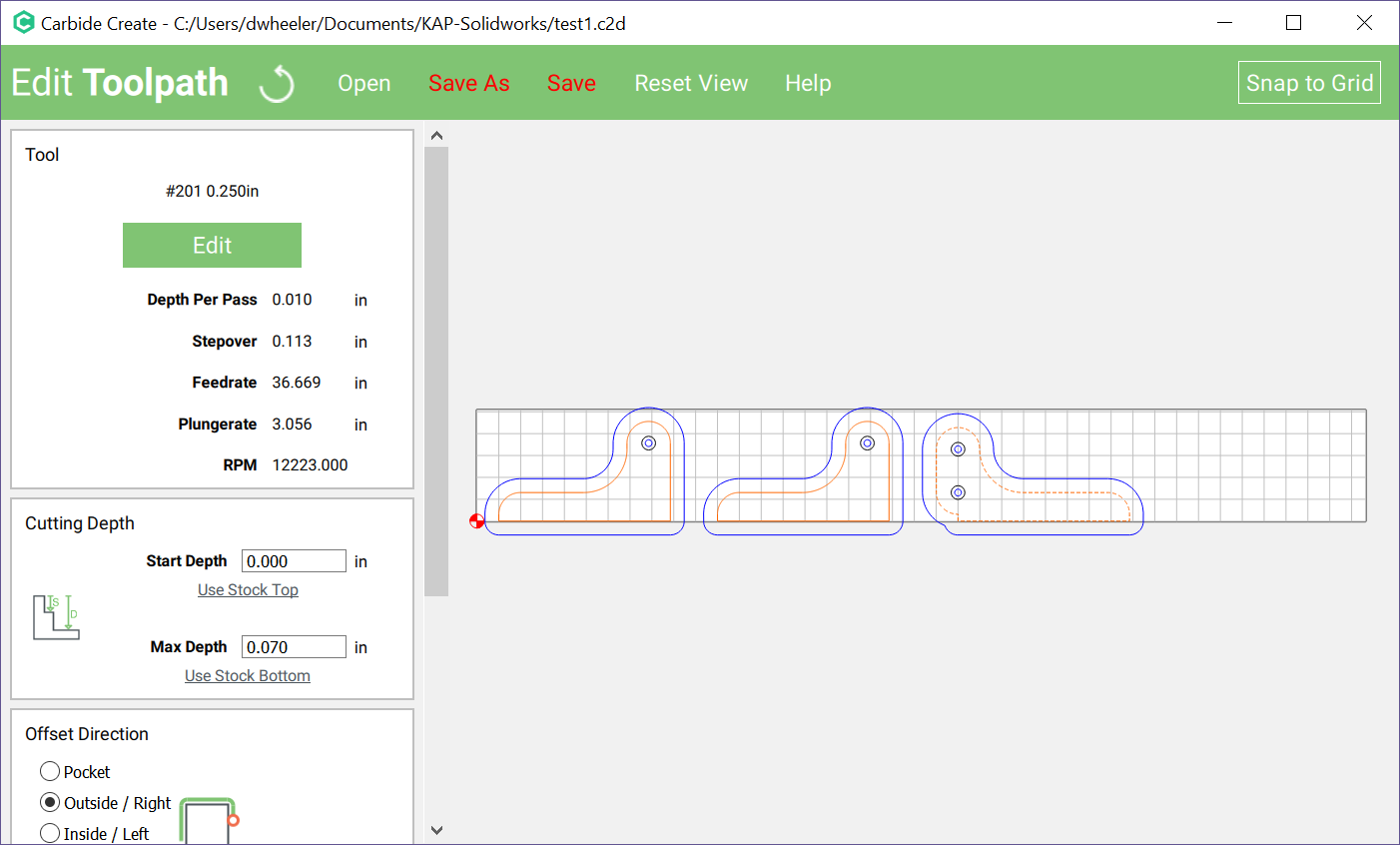

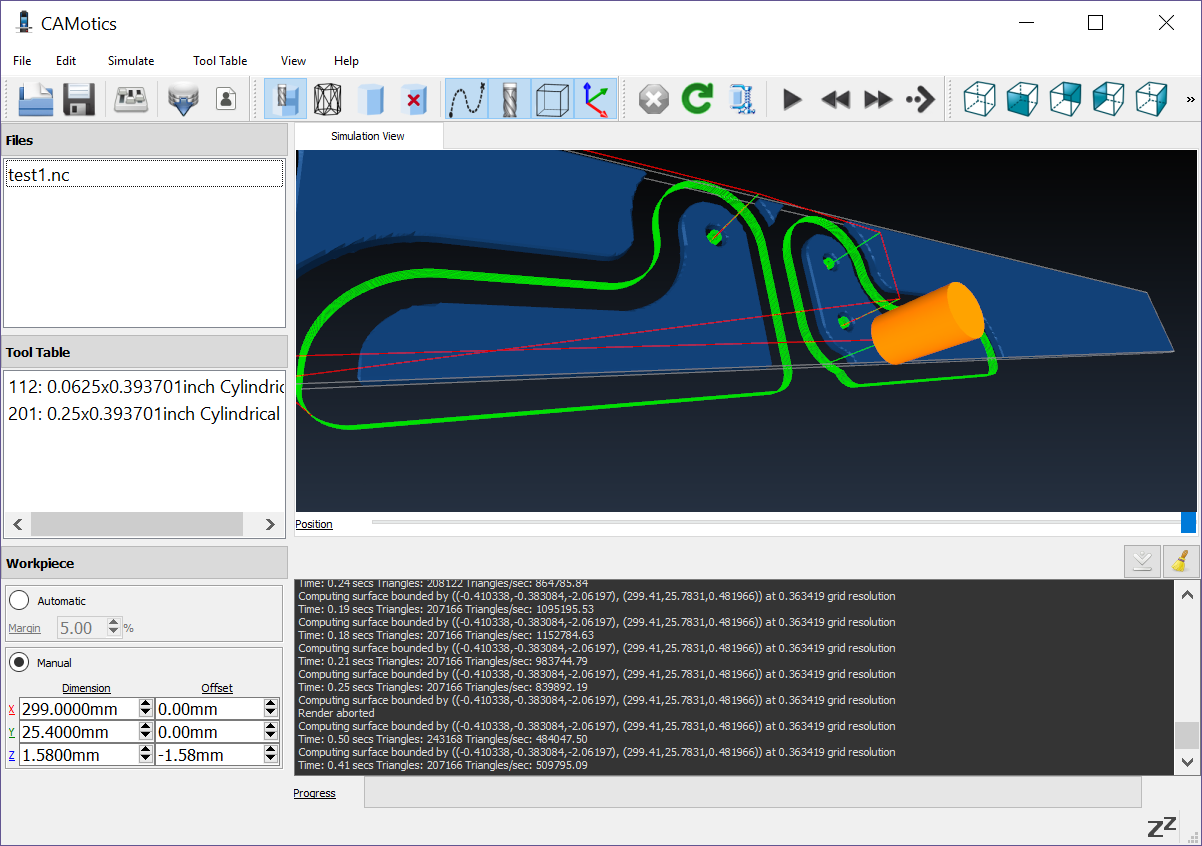

I’m trying to decide if I should jump in and purchase a Shapeoko. I figured before spending the money I could try out the workflow to see if I would really be able to do what I want with it. So I drew up part of a KAP rig, based on aluminum angle stock, exported the shapes as dxf files from solidworks, imported those into Carbide Create, set up tool paths, exported the G-code and simulated the milling operation in Camotics.

The CAD portion of this I did earlier in the week. And the CAM steps I completed yesterday morning. There were a few hiccups along the way. For instance, importing the DXF into Carbide Create it interpreted mm as inches so I had to set a scaling factor. But nothing was fundamentally broken and I was able to work through it all in half a day.

So I think I’m at the point where I need an actual Shapeoko machine to take this to the next step – cutting aluminum.